La Personalización de otras piezas de estampado implica la selección de materiales, el diseño de piezas y técnicas de fabricación adaptadas a los requisitos únicos del proyecto. Al asociarse con fabricantes experimentados, los clientes pueden lograr especificaciones precisas, optimizar el rendimiento y abordar las necesidades de aplicaciones específicas en diversas industrias y proyectos.

En comparación con el estampado de metal ordinario, el estampado de precisión requiere condiciones mucho más estrictas.

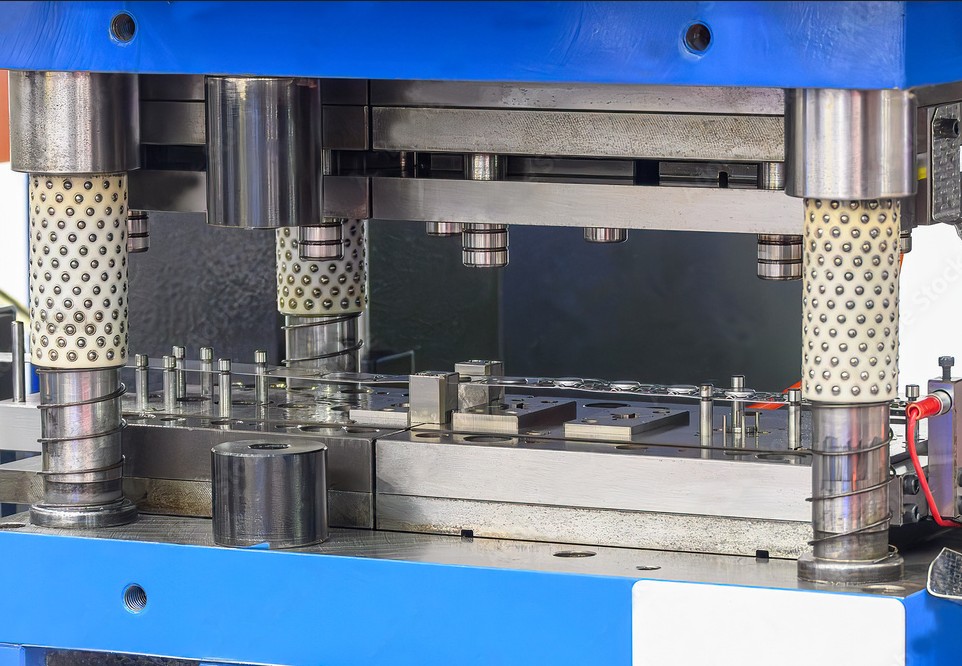

Las matrices de estampado de precisión deben diseñarse con mucha precisión, lo que a menudo requiere un tratamiento preciso de endurecimiento de la superficie. Los troqueles deben tener una buena resistencia al desgaste y durabilidad para garantizar una producción estable a largo plazo.

Los requisitos de calidad de la superficie para los materiales estampados de precisión son muy altos. Las proporciones del material deben ser correctas y consistentes, y la superficie generalmente debe ser lisa, sin arañazos e impecable. Para las materias primas de chapa, tira o bobina, el ancho del material debe estar dentro del rango de tolerancia especificado. Los materiales comunes utilizados para el estampado de precisión incluyen acero inoxidable, aleaciones de aluminio, aleaciones de cobre, etc.

Para el estampado de metal de precisión, el buen diseño y fabricación de la matriz, así como el control estricto de la calidad del material, son esenciales para garantizar la calidad constante del producto en la producción a gran escala.

Los beneficios del uso de otras piezas de estampado incluyen versatilidad del material, propiedades personalizadas y diseños específicos de la aplicación. Estos componentes permiten innovaciones en diversas industrias, abordando requisitos únicos con un rendimiento optimizado, durabilidad y producción rentable, asegurando el éxito de diversos proyectos.

El estampado de metal de precisión es un método de formación en frío, y consta de nueve operaciones de procesamiento:

Extrusión: La pieza en bruto se coloca en la cavidad del molde y se aplica presión para extrudirla del espacio del molde para formar partes huecas o sólidas.

Curling: el extremo de la chapa se enrolla en una cabeza redonda casi cerrada, que generalmente se usa para procesar piezas similares a las bisagras.

Dibujo: La chapa metálica se presiona en partes huecas de cualquier forma usando una matriz, o se deforma aún más para piezas huecas.

Doblado: la chapa se dobla en partes con un cierto ángulo usando una matriz, o se Vuelve a doblar para las piezas predobladas.

Bridas: Los agujeros o bordes exteriores de la chapa se convierten en paredes rectas mediante un troquel.

Abultamiento: la fuerza radial se aplica a la parte hueca mediante un troquel para expandir el diámetro local.

Necking: La presión radial se aplica a la boca de la parte hueca mediante un troquel desde el exterior hacia el interior, reduciendo el diámetro local.

Expansión: Método de deformación que amplía la dimensión radial de un espacio en blanco hueco o tubular en una ubicación determinada.

Recorte: Aplanar la superficie desigual de la pieza de trabajo; Presionar la pieza de trabajo ya doblada o dibujada en la forma correcta.

El equipo utilizado para el estampado incluye prensas manuales, prensas mecánicas, prensas hidráulicas, prensas neumáticas, prensas mecánicas de alta velocidad, prensas CNC y prensas de precisión.

Los componentes Estampados de Precisión se utilizan ampliamente en diversas industrias, y la participación de HHC se extiende, pero no se limita a, los siguientes sectores:

Industria automotriz: Los componentes Estampados de Precisión se utilizan en la fabricación de varias piezas en automóviles, incluidas las estructuras de carrocería, los asientos, los motores, los sistemas de suspensión y los sistemas de transmisión.

Industria de la electrónica: Los componentes Estampados de Precisión se utilizan para la fabricación de recintos, conectores, disipadores de calor y componentes conductores en productos electrónicos.

Industria eléctrica: Los componentes Estampados de Precisión se emplean en la producción de terminales, bloques de terminales, interruptores y enchufes para equipos eléctricos.

Industria de las telecomunicaciones: Los componentes Estampados de Precisión son esenciales para la fabricación de componentes críticos como antenas, conectores y recintos de protección en equipos de telecomunicaciones.

Equipo médico: Los componentes Estampados de Precisión se utilizan en dispositivos médicos para la fabricación de recintos, piezas de instrumentos, catéteres y conectores.

Nueva industria energética: Los componentes Estampados de Precisión juegan un papel crucial enSectores como los vehículos de nueva energía, la energía fotovoltaica y la energía eólica, utilizados en la fabricación de componentes de baterías, paneles solares y partes de turbinas eólicas.

Electrodomésticos: Los componentes Estampados de Precisión se utilizan en electrodomésticos para la fabricación de carcasas, botones, interruptores y piezas de motor.

Industria aeroespacial: Los componentes estampados de precisión se utilizan en el sector aeroespacial para fabricar estructuras de aviones, partes de motores y componentes de naves espaciales.

A continuación se muestran las ventajas de servicio que ofrecemos para los componentes de estampado de metal de precisión personalizados:

Soporte de diseño de ingeniería: Contamos con un equipo de ingeniería experimentado que puede proporcionar soporte de diseño profesional para ayudar a optimizar los diseños de productos, mejorar el rendimiento del producto y reducir los costos para nuestros clientes.

Producción personalizada: podemos personalizar los componentes de estampado de metal de precisión de acuerdo con los requisitos específicos del cliente, incluidas las dimensiones, formas, materiales, tratamientos de superficie, etc., para satisfacer las necesidades individualizadas.

Equipo de producción avanzado: Poseemos equipos avanzados de estampación y mecanizado, que incluyen prensas de alta velocidad, prensas de punzón CNC, prensas de precisión, etc., lo que nos permite lograr una producción eficiente y de alta precisión.

Control de calidad estricto: Hemos establecido un sistema de gestión de calidad integral que cubre todas las etapas, desde la adquisición de materias primas hasta el control del proceso de producción y la inspección final del producto. Esto asegura la calidad del producto estable y confiable.

Capacidad de producción flexible: Tenemos capacidades de producción flexibles y podemos ajustar rápidamente la producción de acuerdo con los volúmenes de pedidos del cliente para garantizar la entrega oportuna y satisfacer las demandas del cliente.

Servicio integral de posventa: Proporcionamos servicios posventa integrales, incluyendo orientación sobre el uso del producto, soporte técnico y mantenimiento posventa, para garantizar que cualquier problema que encuentren los clientes durante el uso del producto se pueda abordar con prontitud.

Con estas ventajas de servicio, estamos comprometidos a proporcionar a los clientes componentes de estampado de metal de precisión personalizada de alta calidad y alto rendimiento, ayudándoles a mejorar la innovación y competitividad del producto en el mercado.