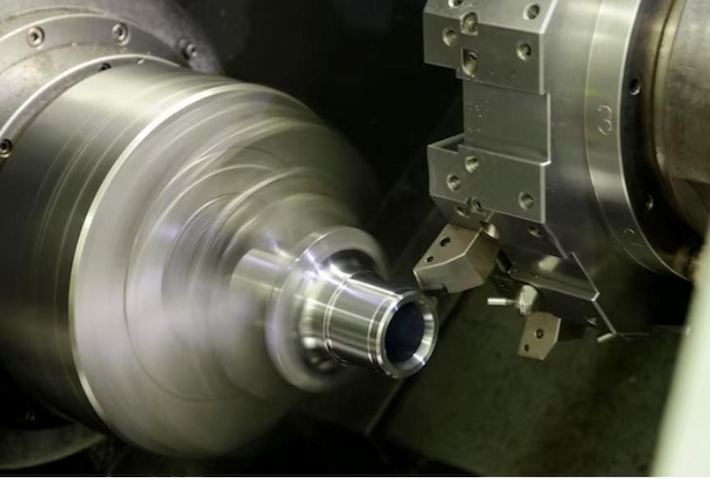

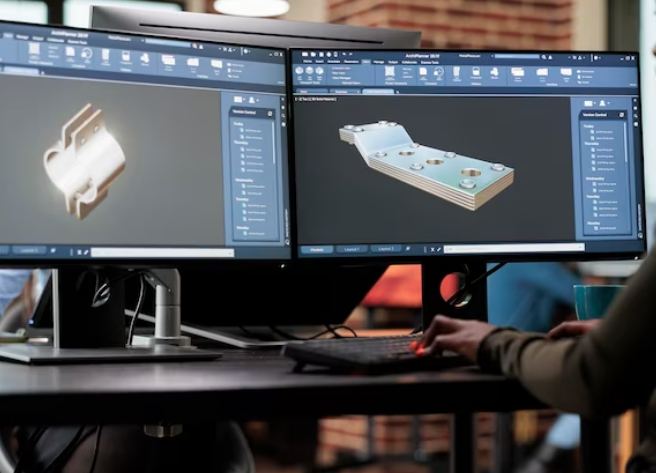

El torneado CNC es un proceso en el que se utiliza una máquina de torno para dar forma a la materia prima en un producto terminado. La última tecnología para piezas de torneado CNC implica el uso de software y sistemas de hardware avanzados que permiten una producción más rápida, más precisa y más eficiente. Esta tecnología incluye sistemas de monitoreo y retroalimentación en tiempo real que permiten a los operadores ajustar los parámetros de mecanizado sobre la marcha, así como soluciones de herramientas y mantenimiento de trabajo de vanguardia que mejoran la rigidez y reducen los tiempos de configuración. Además, la integración de sistemas de automatización y robótica en las operaciones de torneado CNC se está volviendo cada vez más común, lo que permite un ahorro de productividad y costos aún mayor. En general, la última tecnología para piezas de torneado CNC está revolucionando la industria manufacturera al mejorar la calidad, reducir los tiempos de entrega y aumentar el rendimiento.

Lograr precisión con piezas de torneado CNC requiere una combinación de factores, incluida la tecnología avanzada de la máquina, herramientas de alta calidad y operadores capacitados. La clave de la precisión radica en una planificación y ejecución cuidadosas del proceso de mecanizado, con un enfoque en optimizar los parámetros de corte, minimizar el desgaste de la herramienta y garantizar la configuración y alineación adecuadas de la pieza de trabajo. Además, las medidas continuas de monitoreo y control de calidad son esenciales para mantener la precisión y la consistencia durante toda la producción. Con las herramientas, técnicas y experiencia adecuadas, el torneado CNC puede lograr altos niveles de precisión y precisión dimensional incluso en las partes más complejas.

En el ámbito del mecanizado de control numérico por computadora (CNC), dos procesos fundamentales, el torneado y el fresado, desempeñan un papel fundamental en la configuración de las materias primas en componentes de ingeniería de precisión. Comprender las diferencias clave entre el torneado CNC y el fresado es crucial para los fabricantes e ingenieros con el objetivo de optimizar sus procesos de mecanizado y lograr resultados superiores. En este artículo, profundizamos en las características distintivas del torneado y fresado CNC, arrojando luz sobre sus aplicaciones, técnicas y ventajas.

Torneado CNC: el torneado es un proceso de mecanizado que se utiliza principalmente para componentes cilíndricos. DuranteMecanizado CNC de acero inoxidable, Una pieza de trabajo gira sobre un husillo, y una herramienta de corte atraviesa a lo largo del eje de rotación para dar forma al material. Este proceso es ideal para crear piezas como ejes, pasadores y superficies cilíndricas.

Fresado CNC: El fresado, por otro lado, implica la eliminación de material de una pieza de trabajo mediante cortadores rotativos. La pieza de trabajo permanece estacionaria, mientras que la herramienta de la fresadora se mueve a lo largo de varios ejes para crear formas, ranuras y agujeros complejos. El fresado CNC es versátil y aplicable a una amplia gama de geometrías.

Torneado CNC: las máquinas de torneado, también conocidas como tornos, tienen una orientación de husillo horizontal o vertical. La pieza de trabajo se sujeta al husillo, que gira, lo que permite que la herramienta de corte se mueva paralela al eje de rotación.

Fresado CNC: Las fresadoras pueden tener orientaciones de husillo vertical u horizontal. En el fresado vertical, el husillo está orientado verticalmente, mientras que en el fresado horizontal, el husillo se coloca horizontalmente. Esta distinción permite diferentes enfoques de corte.

Torneado CNC: las herramientas de torneado suelen ser herramientas de un solo punto que cortan material a medida que gira la pieza de trabajo. La herramienta se mueve radialmente y axialmente para dar forma a la pieza.

Fresado CNC: las herramientas de fresado suelen ser herramientas multipunto, y el proceso de mecanizado implica movimientos giratorios y lineales. El fresado permite el uso de molinos finales, molinos frontales y varias geometrías de herramientas para lograr resultados específicos.

Torneado CNC: el torneado es el más adecuado para piezas simétricas con simetría rotacional. Se destaca en la creación de características como ranuras, estrechamientos y contornos en superficies cilíndricas. Las aplicaciones comunes incluyen la producción de componentes cilíndricos como casquillos, ejes y bridas.

Fresado CNC: el fresado es experto en producir una amplia variedad de formas, incluidos bolsillos, ranuras y contornos tridimensionales complejos. Esta versatilidad hace que el fresado sea adecuado para componentes intrincados. El fresado es adecuado para una gama más amplia de aplicaciones, incluida la creación de componentes intrincados para las industrias aeroespacial, automotriz y médica.

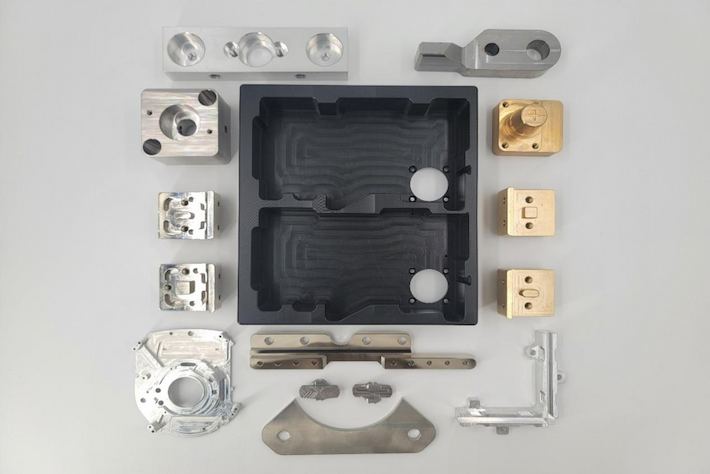

En conclusión, el fresado CNC el torneado y son distintos procesos de mecanizado, cada uno con su propio conjunto de ventajas y aplicaciones. La elección entre el torneado y el fresado depende de factores como la geometría deseada, el material y los requisitos del proyecto. Al comprender las diferencias entre el torneado y el fresado, elegir el método de mecanizado apropiado puede resultar en la producción de productos de alta calidad.

En el ámbito del mecanizado CNC, HHC (Iniule) se destaca como la mejor opción para el torneado CNC, ofreciendo una experiencia incomparable y soluciones personalizadas. Estas son las razones clave por las que seleccionar HHC es una decisión estratégica:

Como profesionalFábrica de piezas de alta precisión, HHC se destaca en el desarrollo de moldes personalizados y el diseño de soluciones personalizadas, proporcionando soluciones de fabricación personalizadas. Nuestra experiencia radica en la creación de moldes a medida, asegurando la precisión y singularidad de los componentes adaptados a las necesidades específicas de su proyecto.

En HHC, la calidad es nuestra piedra angular. Cumpliendo con los estándares internacionales como ISO9001, IATF16949 e ISO13485, etc. Garantizamos la excelencia en cada producto. Nuestros rigurosos procesos de control de calidad garantizan que cada componente no solo cumpla con las expectativas del cliente, lo que establece confianza y confiabilidad.

HHC cuenta con un parque industrial de construcción propia, que integra verticalmente nuestra cadena de producción para una clara ventaja de costos. Nuestros procesos de producción eficientes e integración vertical mejoran la productividad, lo que nos permite cumplir con su presupuesto de costos sin comprometer la calidad.

En conclusión, HHC CNC Lathing Turning ofrece más que mecanizado de precisión; proporciona una asociación arraigada en la innovación, la confiabilidad y la rentabilidad. Elija HHC para un viaje colaborativo que fusiona la excelencia personalizada con una calidad incomparable, todo mientras optimiza los costos.

En el mundo del mecanizado de precisión, el torneado CNC es un proceso versátil reconocido por su capacidad para crear varias formas con precisión y eficiencia. Aquí hay una exploración concisa de las formas que puede producir el torneado CNC:

El torneado CNC sobresale en la elaboración de formas cilíndricas, lo que lo hace ideal para producir componentes como ejes, pasadores y casquillos. El proceso asegura uniformidad y precisión en perfiles cilíndricos.

El torneado CNC es competente en la creación de estreches y formas cónicas. Esta capacidad es valiosa para aplicaciones en las que las piezas requieren una reducción gradual o una expansión de diámetro.

El proceso es experto en formar intrincados surcos y contornos en superficies cilíndricas. Esto hace que el torneado CNC sea adecuado para componentes con características detalladas, mejorando tanto la funcionalidad como la estética.

Aunque se asocia principalmente con formas cilíndricas, el torneado CNC también se puede emplear para producir componentes esféricos. Esta versatilidad amplía la gama de formas alcanzables.

El torneado CNC puede manejar geometrías complejas, incluidas formas con diferentes diámetros y detalles intrincados. Esto lo convierte en un proceso valioso para elaborar componentes diversos y personalizados.

En conclusión, el torneado CNC no se limita a formas específicas; su adaptabilidad permite la creación de una amplia gama de componentes, que van desde formas cilíndricas simples hasta geometrías intrincadas y complejas. La precisión y la eficiencia del torneado CNC lo convierten en una opción preferida para dar forma a varias piezas en el real.