En nuestra empresa, utilizamos un proceso altamente eficiente para producir piezas de mecanizado CNC que cumplen con los requisitos específicos de nuestros clientes. Aquí hay una descripción general del proceso que seguimos:

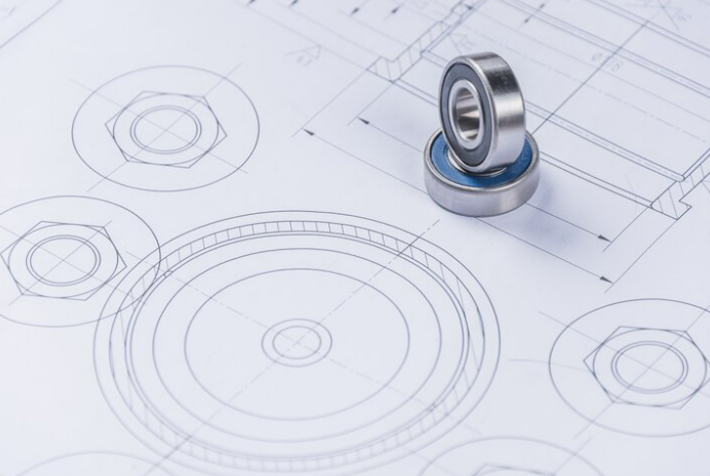

Diseño y Programación: Nuestros ingenieros expertos trabajan con el último software para diseñar y programar la pieza, asegurando que cumpla con las especificaciones y tolerancias requeridas.

Selección de material: Seleccionamos cuidadosamente el material apropiado para la pieza, teniendo en cuenta su resistencia, durabilidad y otras propiedades.

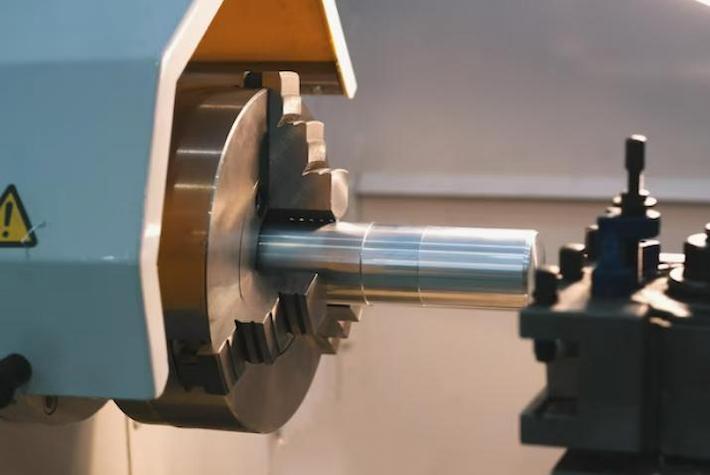

Mecanizado CNC: Utilizamos máquinas avanzadas controladas por computadora para realizar el proceso de mecanizado CNC, que implica eliminar el exceso de material de la pieza de trabajo para crear la forma final de la pieza.

Inspección de calidad: Nuestro equipo inspecciona las piezas en cada etapa del proceso, utilizando la última tecnología y el equipo para garantizar que cada Parte cumpla con los estándares de calidad requeridos.

Acabado: Ofrecemos una gama de opciones de acabado, incluyendo chorro de arena, pulido, anodizado y revestimiento, para mejorar la apariencia y funcionalidad de las piezas.

Embalaje y envío: empaquetamos cuidadosamente las piezas para garantizar su llegada segura y entregarlas rápidamente a nuestros clientes.

Con nuestro compromiso con la calidad, la eficiencia y la satisfacción del cliente, hemos construido una reputación como un proveedor confiable de piezas de mecanizado CNC personalizadas. Si tiene un proyecto que requiere piezas de mecanizado CNC de alta calidad, póngase en contacto con nosotros para discutir sus requisitos y cómo podemos ayudar.

Descripción | Fresado CNC | Torneado CNC |

Materiales | Aluminio/Cu/acero/inoxidable | Aluminio/Cu/acero/inoxidable |

Tamaño máximo de la parte | 1000mm * 1000mm * 600mm | 1000mm * 600mm * 600mm |

Plazo de entrega estándar | 4 días hábiles | 4 días hábiles |

Tolerancia (± mm) | Sólo fresado: Hasta ± 0.025mm Con corte de alambre o EDM: hasta 0.002mm | Hasta ± 0,0025mm |

Garantía de calidad | ISO 9001, ISO 45001:2018 Auditorías de proveedores Proyector de medición CMM y 2D Informes de inspección Inspección funcional Muestreo personalizado | ISO 9001, ISO 45001:2018 Auditorías de proveedores Proyector de medición CMM y 2D Informes de inspección Inspección funcional Muestreo personalizado |

Alta precisión y precisión: con el mecanizado CNC, las piezas se pueden fabricar con tolerancias extremadamente ajustadas y alta precisión, lo que proporciona un nivel de consistencia que es difícil de lograr con los procesos de mecanizado manual.

Amplia gama de materiales: el mecanizado CNC se puede utilizar con una variedad de materiales, incluyendo metal, plástico, madera y compuestos.

Rentable para la producción de gran volumen: el mecanizado CNC es ideal para la fabricación de gran volumen, ya que permite la producción de grandes cantidades de piezas a un menor costo por pieza.

Mayor eficiencia: la naturaleza automatizada del mecanizado CNC significa que la producción se puede llevar a cabo de manera más eficiente, sin necesidad de intervención manual, lo que resulta en tiempos de producción más rápidos.

Versatilidad: el mecanizado CNC se puede utilizar para producir componentes complejos con formas y geometrías intrincadas, lo que lo hace adecuado para una amplia gama de aplicaciones.

En el ámbito de la fabricación de precisión, el mecanizado Computer Numerical Control (CNC) se erige como una maravilla tecnológica que ha revolucionado la industria productiva. El mecanizado CNC implica el uso de sistemas computarizados para controlar máquinas herramienta y procesos, lo que permite una producción altamente precisa y eficiente de piezas y componentes intrincados. Los diversos procesos de mecanizado CNC bajo HHC tienen diferentes ámbitos de aplicación y características de procesamiento. Lo siguiente proporciona una clasificación detallada e introducción.

Uno de los tipos más comunes de mecanizado CNC, el fresado emplea herramientas de corte rotativas para eliminar material de una pieza de trabajo. La fresadora puede moverse a lo largo de varios ejes, creando una amplia gama de formas, ranuras y agujeros. Desde componentes simples hasta prototipos complejos, el fresado es versátil y se usa ampliamente en industrias como la aeroespacial, automotriz y electrónica.

En las operaciones de giro, la pieza de trabajo gira mientras una herramienta de corte la forma en la forma deseada. Este tipo de mecanizado CNC es ideal para crear componentes cilíndricos como ejes, pernos y husillos. El torneado de precisión es una piedra angular de los procesos de fabricación, ya que proporciona eficiencia y precisión para diversas aplicaciones.

Como su nombre indica, las máquinas CNC de perforación están diseñadas para crear agujeros en las piezas de trabajo. Estas máquinas utilizan brocas giratorias para eliminar material y son cruciales en la producción de componentes que requieren orificios precisos y uniformes. Industrias como la construcción, la metalmecánica y la electrónica dependen en gran medida de la perforación CNC para sus necesidades de fabricación.

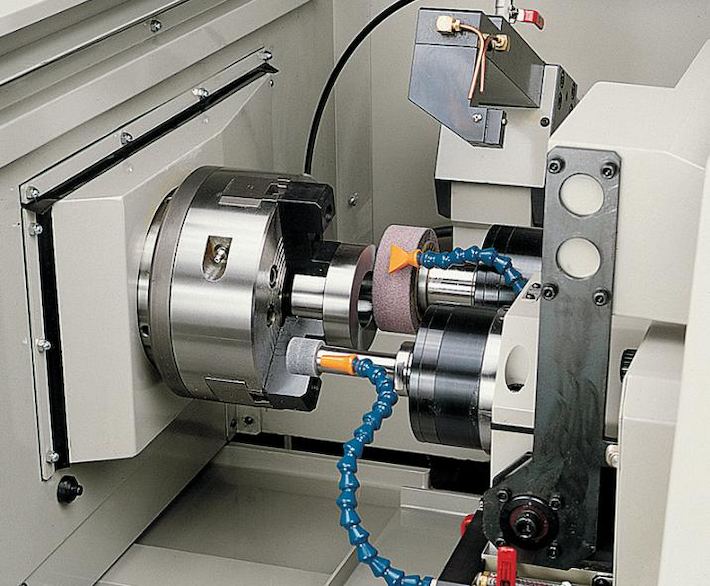

Cuando la precisión extrema y el acabado superficial son primordiales, entra en juego el pulido CNC. Este método emplea ruedas abrasivas para eliminar material y lograr tolerancias estrictas. La molienda CNC es indispensable en la producción de herramientas, moldes y componentes de alta precisión utilizados en dispositivos médicos e ingeniería aeroespacial.

EDM es un método de mecanizado CNC no tradicional que utiliza descargas eléctricas para dar forma a los materiales. Mediante chispas eléctricas cuidadosamente controladas, EDM puede crear formas intrincadas y complejas con alta precisión. Esta técnica es particularmente útil para metales duros que son desafiantes para la máquina con métodos tradicionales. Por ejemplo, utilizamos el mecanizado de descarga eléctrica (EDM) para personalizar plantillas para moldes

El corte por láser CNC implica el uso de un rayo láser para cortar materiales, creando bordes precisos y limpios. Este método es ampliamente utilizado en la fabricación de componentes de chapa para industrias que van desde la automoción hasta la electrónica de consumo. El alto nivel de precisión y velocidad hace que el corte por láser CNC sea un proceso invaluable en la fabricación moderna.

En el panorama en constante evolución de la fabricación, dos tecnologías de vanguardia han surgido como pioneras: el mecanizado CNC y la impresión 3D. Cada método trae su propio conjunto de fortalezas y aplicaciones a la mesa. Profundizcamos en las complejidades del mecanizado CNC y la impresión 3D, comparando sus características, ventajas y limitaciones.

El mecanizado CNC (control numérico informático) es un proceso de fabricación sustractivo. Implica eliminar material de una pieza de trabajo para lograr la forma deseada. Este proceso utiliza diseño asistido por computadora (CAD) y software de fabricación asistida por computadora (CAM) para controlar con precisión el movimiento de las herramientas de corte.

El mecanizado CNC es conocido por su alto nivel de precisión y precisión. Puede lograr tolerancias estrictas y producir detalles intrincados, lo que lo hace adecuado para aplicaciones donde la precisión es primordial, como las industrias aeroespacial y médica. El mecanizado CNC es versátil cuando se trata de compatibilidad de materiales. Puede manejar una amplia gama de materiales, incluidos metales, plásticos y compuestos. Esto lo convierte en una opción preferida para las industrias que exigen durabilidad y resistencia en sus componentes. El mecanizado CNC es adecuado tanto para la creación de prototipos como para la producción a gran escala. Si bien el tiempo de configuración para el mecanizado CNC puede ser más largo que la impresión 3D, se destaca en la producción de piezas funcionales de alta calidad. El mecanizado CNC proporciona un acabado superficial superior en comparación con muchas tecnologías de impresión 3D. Esto lo convierte en una opción ideal para componentes que requieren una superficie pulida o lisa.

La impresión 3D, o fabricación aditiva, construye objetosCapa por capa de un modelo digital. Implica depositar material en un patrón específico para crear un objeto tridimensional. Este proceso es altamente versátil y permite geometrías intrincadas.

La impresión 3D admite una amplia gama de materiales, incluidos plásticos, metales, cerámica e incluso bio-materiales. Las opciones de materiales continúan expandiéndose, abriendo nuevas posibilidades para varias industrias. La impresión 3D destaca en la creación rápida de prototipos y es adecuada para geometrías complejas que pueden ser un desafío para el mecanizado CNC. Sin embargo, puede que no coincida con la velocidad del mecanizado CNC para la producción a gran escala. En términos de rentabilidad, especialmente para la producción de bajo volumen y la creación de prototipos, la impresión 3D puede ofrecer ventajas debido a la reducción del desperdicio de material y las configuraciones más simples. La impresión 3D se celebra por sus capacidades de personalización. Permite la creación de diseños únicos y personalizados sin necesidad de herramientas adicionales, lo que lo hace ideal para la producción única o de lotes pequeños.

En general, la elección entre el mecanizado CNC 3D depende de factores como los materiales y la impresión, los requisitos de precisión, la escala de producción y la complejidad del proyecto. Para carreras de producción más grandes, el mecanizado CNC destaca en precisión y versatilidad de materiales, mientras que la impresión 3D brilla en la creación rápida de prototipos y aplicaciones de diseño complejas.

Cationes.

El mecanizado CNC (Control Numérico por computadora) juega un papel crucial en la fabricación de componentes de precisión de alta calidad. A continuación se muestran los pasos generales del proceso y los detalles para la fabricación de bridas mecanizadas con CNC:

Pasos de proceso para bridas mecanizadas CNC:

1. Diseño y modelado:

Antes de fabricar componentes CNC, el diseño CAD (diseño asistido por computadora) es esencial. Los ingenieros de diseño utilizan software CAD para crear un modelo 3D de la pestaña, determinando formas geométricas, dimensiones y trayectorias de mecanizado.

2. Material de preparación:

Elija materias primas apropiadas, típicamente metales (como acero inoxidable, aluminio, etc.). La selección de materiales depende del propósito de la pestaña, el entorno de trabajo y los requisitos de rendimiento.

3. Procesos de mecanizado:

A. Desbaste:

Use herramientas de corte en máquinas CNC para realizar desbaste, dando forma aproximadamente a la forma general de la pieza de trabajo.

El objetivo de desbaste es eliminar rápidamente el exceso de material, dejando una forma final aproximada.

B. Semi-Acabado:

Use diferentes herramientas para semiterminar la pieza de trabajo, acercándose aún más a la forma final.

Reducir la velocidad de corte para mejorar la suavidad de la superficie.

C. Acabado:

Utilice pequeñas herramientas para el corte de precisión final, logrando las dimensiones finales y la suavidad de la superficie.

El acabado a menudo implica el uso de herramientas más pequeñas para mejorar la precisión del mecanizado.

D. Mecanizado de agujeros y corte de rosca:

Use herramientas especializadas para el mecanizado de orificios y el corte de roscas para garantizar que la brida cumpla con las especificaciones de diseño.

4. inspección y control de calidad:

Después de cada paso de mecanizado, realice inspecciones para garantizar que las dimensiones, la forma y la calidad de la superficie de la pieza de trabajo cumplan con los requisitos de especificación. Los métodos de inspección comunes incluyen medición de coordenadas, pruebas de rugosidad de superficie y pruebas ultrasónicas.

5. Tratamiento superficial:

Dependiendo de los requisitos, realice tratamientos superficiales como pulido, chorro de arena o revestimiento para mejorar la apariencia y la resistencia a la corrosión.

6. Embalaje y entrega:

Después de completar el mecanizado y la inspección, empaquetar las bridas de acuerdo con los requisitos del cliente y proceder con la entrega.

El mecanizado CNC (Control Numérico Informático) es un proceso de fabricación en el que el software informático preprogramado controla el movimiento de maquinaria y herramientas. Este proceso permite la creación de piezas muy precisas y complejas a partir de diversos materiales, incluidos metales y plásticos. El mecanizado CNC es ampliamente utilizado en industrias como automotriz, electrónica y aeroespacial.

El torneado CNC es ideal para producir piezas cilíndricas o redondas, como ejes, bujes, tornillos y pasadores. Se usa comúnmente para componentes que requieren alta precisión y superficies lisas. Industrias como la automoción, la medicina y la electrónica se benefician deChina piezas tornadas de aluminio...

Busque un proveedor con amplia experiencia, equipos modernos y un fuerte compromiso con el control de calidad. Certificaciones como ISO 9001 e IATF 16949 indican el cumplimiento de los estándares de la industria. Además, considere factores como la capacidad de producción, los plazos de entrega y las opiniones de los clientes.

En HHC, ofrecemos piezas de precisión con tolerancias tan ajustadas como ± 0,01mm, lo que garantiza una alta precisión incluso para los componentes más complejos. Nuestro equipo avanzado nos permite mantener la consistencia y cumplir con los requisitos específicos de cada proyecto.

Los tiempos de entrega varían según la complejidad y la cantidad de las piezas, pero normalmente entregamos piezas de mecanizado CNC en 1 a 4 semanas. También ofrecemos servicios acelerados para proyectos urgentes para ayudar a nuestros clientes a cumplir con plazos ajustados.